How a Dairy Queen Franchisee Saved Thousands on Spoiled Food

Home / How a Dairy Queen Franchisee Saved Thousands on Spoiled Food

It was a typical summer at a busy Dairy Queen franchise in Augusta, GA. Orders continued to roll in, customers wanted ice cream, and staff rushed to keep up. But behind the scenes, the store had a costly problem. Food spoilage was draining profits.

Temperatures in freezers and coolers were manually checked. Employees recorded data manually. Mistakes happened often. Spoiled food meant money wasted.

The franchise owner knew something had to change.

The Challenge of Manual Monitoring

Before switching to Inovisense, the Dairy Queen team relied on staff checking fridge and freezer temperatures. They wrote the numbers down on clipboards. It was slow and unreliable.

On busy days, these manual checks got skipped. Small mistakes led to significant losses. Just one forgotten check could mean spoiled ice cream or unsafe food. Costs rose quickly.

They needed a reliable temperature monitoring system for restaurants. A solution was needed to prevent food spoilage, keep customers safe, and save the store money.

How Inovisense Solved the Problem

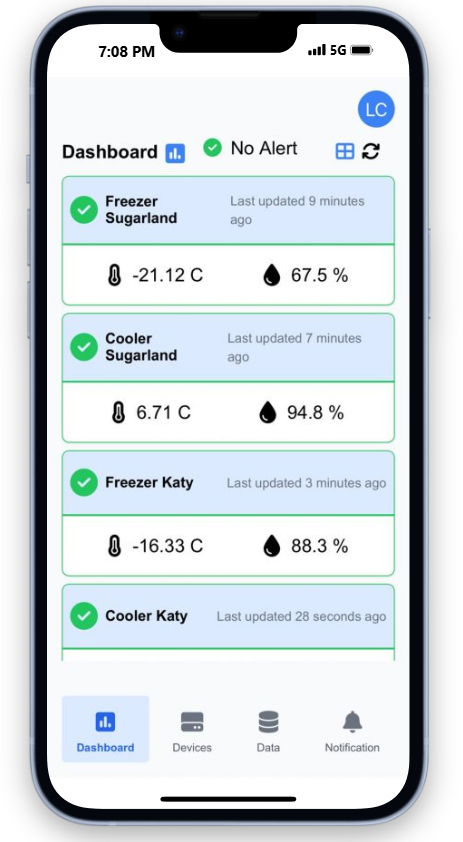

The franchise owner chose Inovisense’s temperature and humidity monitoring system. It provided continuous remote restaurant temperature monitoring. Wireless temperature monitoring for restaurants sensors were placed in storage areas, including a walk-in cooler temperature sensor and freezer monitoring.

The sensors collected data automatically. Temperatures were sent directly to a cloud-based restaurant monitoring system. Employees no longer needed clipboards or manual checks.

Fridge and freezer temperature alerts were sent instantly if temperatures exceeded safe ranges. Notifications came through emails and phones. Staff could act right away to protect the food. The Inovisense system also learns each freezer’s defrost cycle to avoid sending false alerts during normal temperature fluctuations.